We’ve wanted to build an earth oven for some time now – we have a small camper oven, but it doesn’t really work that well, and we like to use the abundant free oak wood for fuel when we can, rather than pay for propane. We finally got our chance to try our hands at it at Habitable Spaces – where they encouraged us to build some kind of structure before we left.

Three unrelated projects that we’d helped with in December & January led us to decide on the earth oven build:

First, when we were digging postholes to fence off their first major field, we discovered that the subsoil was a rich, malleable clay, perfect for sculpting and building with.

Secondly, we dismantled and felled the giant tower, made from three massive cable spools stacked upon one another – revealing a perfectly useable concrete foundation pad beneath.

Third, we’d spent a lot of time scavenging the ruins of two old homesteads on their property, which had been home to Shane’s grandmother and other ancestors. We metal detected and scrounged, and Gabe created a skullpture with items we discovered throughout January.

In our scavenging, we discovered piles of old bricks, and several dozen partially-buried split limestone blocks, at both sites – these had once been house foundations. We’d excavated them when we found them, and left them propped up on the surface for possible retrieval later on.

Once we realized we wanted to create an earth oven, we decided these blocks would be the perfect base to build upon – beautiful, free, and full of the character and history of the land. So we borrowed the farm truck and a wheelbarrow, and got to collecting …

Kristin ordered a book on earth oven construction – this would be our Bible for the duration of the construction project that we embarked on, not sure if we’d even have time to finish it before we had to head to Austin in three weeks …

We began mortaring in the blocks, one tier at a time, spending hours fitting the stones together with minimal gaps and maximum stability/levelness.

Next we mixed the first batch of insulation – clay slip and pine shavings – the shavings dry up and even burn out completely, leaving air pockets and a clay-foam heat barrier.

The insulating clay was used to fill a foot-deep layer designed to prevent the infinite thermal heat sink of the ground from leaching away the oven’s heat. We included a layer of wine bottles, and a layer of beer bottles (from the bottle house supply pile) – these would form stable insulating air pockets within the insulation clay.

Once we got within four inches of the top of the base, we paused to mix up a batch of “oven mud” – clay and coarse sand. Oven mud clay is designed to hold heat for baking – it would be roughly the same clay used to build the interior of the oven dome, later on.

The sand we were using was quite rough & coarse – ideal for structural stability, but also quite good at abrading one’s feet completely off. We quickly switched to our rubber muck boots for stomp-mixing. (It might have been easier if the mix was wetter, but we wanted to avoid slumping and long drying times, so we kept it as dry as possible.)

The first batch of oven mud was used to make an oven pad, in the same dimensions as the firebrick interior baking floor would have (we laid out the firebricks on the ground to determine the measurements).

Then we filled in the surrounding gaps with more insulation mix, keeping everything level with the top exterior bricks.

In the meantime, we’d created several “test bricks” with different proportions of sand and clay – as well as one of pure soil (from the layer above the clay, but beneath the topsoil).

For the oven interior dome, we wanted to find what ratio would be strongest, and crack or shrink the least. The bricks dried out over a couple of days while we prepared for next steps and gave the water-soaked base insulation time to dry out some.

Next we worked on the arch opening. The book said that the ideal opening height was 63% of the interior dome, but we had to go just slightly higher to get a nice stable arch, with good supportive edge-to-edge contact throughout. We also tested to make sure that Habitable Spaces’ pizza peel would fit through (yep, just right!)

The resulting arch shape was traced onto plywood – Ali helped cut out two pieces in the proper shape and build a form by joining them together with 2x4s. This supported the bricks while we spaced them out with pebbles, and filled in the gaps with oven mud mortar.

We also started work on the protective roof – while rain wouldn’t destroy the oven, it would saturate the clay, requiring many more hours of firing time to get it up to temp, and shortening the working life of the oven. There were a couple short pieces of roofing left over from the house and kitchen, perfect for our needs. We scavenged together some cedar posts and scraps with lovely knotty character, wanting to make the roof match the organic, natural appeal of the oven’s base.

Before starting the next phase of the build, we mixed up a huge batch of oven mud, making it a little bit wet and leaving time for it to dry out a bit, before we launched the most significant single piece of the construction – the interior dome.

First, we built the sand mold, like a sandcastle – this was the shape of what would become the void within the oven. We sprayed it with water and patted it tightly as we worked, attempting to create a smooth, flowing interior that fire and hot gas would roll through nicely.

The hardest part of the sand form was the newspaper layer, which would help us remove the sand from the clay later – it was frustrating to get it to stay smooth and in place, but we learned as we went, using lots of water, and smaller pieces of paper.

The sand form and the oven mud interior layer had to be done the same day – we we launched immediately into it.

The going was slow, as we carefully packed the oven mud into place, a fist-sized chunk at a time, maintaining a consistent 3″ thickness, and only applying force into existing clay (not into the fragile sand form). A CD we’d bought in Austin from the musician Kiko Villamizar played on repeat for hours – it was not the first or the last time the album provided the soundtrack to our work, but it was the longest continuous stretch.

We each worked from one side of the arch to the back, meeting in the middle – and then switched sides for the next layer, so that any idiosyncrasies in our individual methods would be evenly distributed on either side, and layered with the other’s style.

Darkness fell, and we set up lights on each side so we could finish the vital layer.

While the interior oven mud layer dried, we left it alone and spent a day working on the protective roof, not wanting to impatiently cause a collapse.

Once it seemed dry and stable, we filled in a couple of drying cracks with oven mud, and pulled out the arch form to reveal the sand within.

Then it was time to scoop out the sand form, and create the void.

Once the oven mud was stable and we’d pulled the sand out, we started on the next layer – 4 inches of the same wood shaving/clay slip insulation that we’d used in the base. This layer went much more quickly – the insulation was simple to mix, and fast to apply and shape in big double handfuls.

The next day, we started the first-ever fire inside – a drying fire, which we kept going for about two straight days, speeding along the drying of the water-soaked insulation – we needed it to be mostly dry before we applied the final exterior clay, and we were quickly running out of time at Habitable Spaces.

In order to use the oven effectively before we left, we had to dry out not just the insulation layer over the dome, but the insulation down in the base – which was now wicking moisture up, into the dome, and out into the air as the top dried out more and more.

While we burned the drying fire for days, we built a baking door out of cedar scraps – this would seal in the heat of the oven after a fire had heated up the clay thoroughly, the embers had been removed, and the pizza or bread or pie was inside.

baking door – plugs the entrance, sealing in heat

We also mocked up a simple “fire door” – not totally necessary, but nice to have on windy days when the fire is struggling to breathe due to turbulence. Cool fresh air comes in the bottom to feed the flames, and hot gases and smoke swirl out the top of the arch and above the door.

It was rainy on the final day of the drying fire, so we put the unfinished roof over the oven as it continued to dehydrate. We prepared for the final coat by mixing up a big batch of exterior mud the day before – this consisted of a new mix:

- some fine playground sand,

- a bunch of subsoil (above the clay layer and beneath the topsoil – we did a soil test with a jar of water that indicated it contained mostly very fine sand),

- some clay (about 1 part to the 2 parts of fine sand), and

- about 3 gallons of fresh cow manure (for the smooth strength of the fine fiber of 7-times digested grass)

Once we had a 2-4″ layer of plaster mud all over, we got to work shaping and decorating – smoothing, adding flame and ember colored rocks around the base and arch, and sculpting flames and heat waves in the mud …

We had just two days left before we were leaving Habitable Spaces – and we were determined to be able to eat some food from the oven before we left!

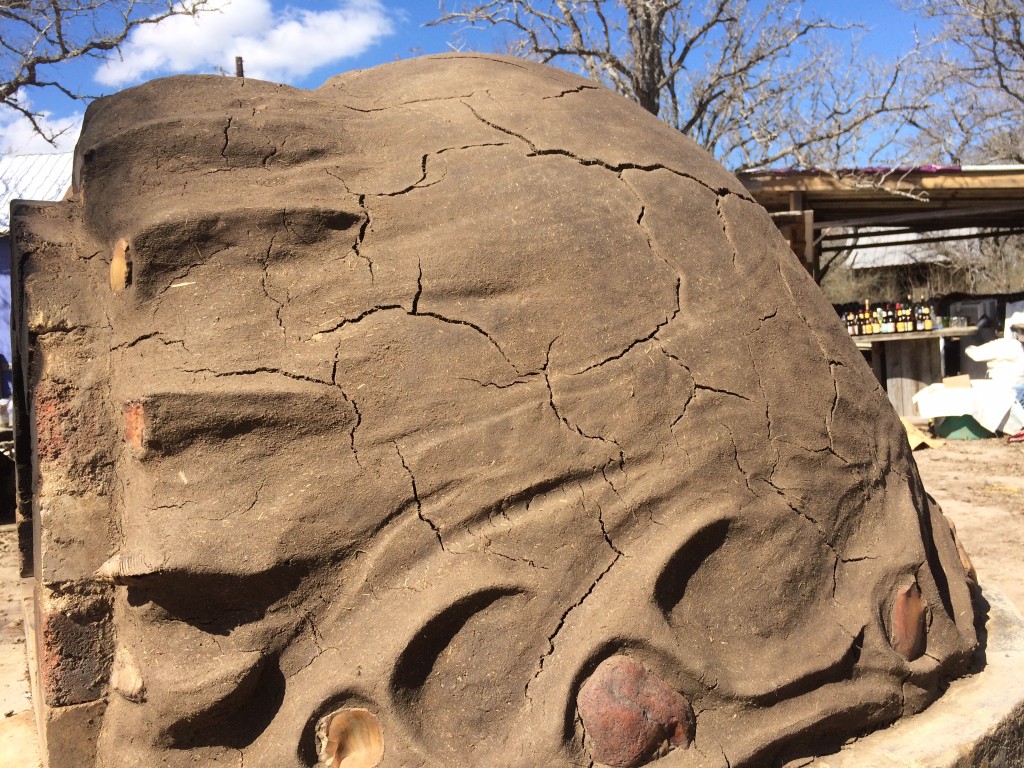

So we started a new drying fire inside, knowing that the fast drying would likely lead to cracking, but willing to take our chances.

There was, indeed, considerable cracking due to the fast-drying action of the fire, but the scary-looking cracks turned out to be easy to fix – we waited until it was dried out and stable, then filled them in with a wet mix of the same plastering material.

The warm exterior (from the sunshine and drying fire) caused the repair slip to dry almost instantly, creating a rough surface – which led us to the discovery that some wirebrushing created a nice light color, which highlighted the flame patterns pleasantly.

We built some tools from the junkpile (a scraper, a cleaning swab, and a fire blowing tube) – and eagerly awaited the next day: our final full day at Habitable Spaces, and the day we would finally test the oven out on some food!

We tinkered and smoothed and prepared throughout the day and the following afternoon …

We kept the drying fire going – now it was going to provide the heat for the first baking!

Kristin prepared two kinds of pizza dough – Neapolitan & New York style, and we soaked the inside of the cedar baking door by floating it in a large bucket, in order to minimize burning/charring.

Finally, we there in the first pizza, which sizzled satisfyingly as it hit the firebrick. Within minutes, delicious scents began wafting from the narrow gaps around the baking door …

And five minutes later, we pulled the first pizza from the oven. (It will take less time in the future, once the oven is finished drying out – at first, it loses efficiency to the energy that water takes to steam out.)

We baked into the night, leaving each pizza in for one minute longer than the last, until we were all too full to eat another slice and we’d exhausted our supply of ingredients. Then we threw a shortbread crust in for awhile, took it out and added a filling of blackberries, apple, ginger, and sugar, and replaced it inside for another 40 minutes of baking.

When it was done (and devoured), we used the considerable remaining heat to overnight slow cook a cast iron pot of beans with jalepenos, pepper, and cumin for our breakfast tacos the following day – our last morning at Habitable Spaces, capping off our wonderful two-month stay!

Postscript:

A couple of days after we left, Shane and Alison sent us the photos below – while they were soaking the door (in preparation for a bakefest of 8 pizzas & a loaf of bread), both a chicken and a cat had decided that the earth oven was a “habitable space,” indeed ….

It was a lot of work but incredibly rewarding and fun – we’re looking forward to visiting again to eat from it someday … and we can’t wait to build our own, back home on our farm!!

What great work on the oven! Now will the QSF be better? How can it possibly be? BTW, were the onions on the maiden voyage pizzas the 48 states approved four syllable version or Minnesota/Wisconsin three syllable (car-mel-ized) version? Bee safe and ya’ll come back now real soon, ya’ hear?

Awesome post and photos, you guys are so rad!