When we saw the Spinning Plates farm profile on the WWOOF-USA website, I just knew it was meant to be – kids about Otis’s age, a scrappy homestead started under circumstances similar to ours- and the possibility of staying in a big old travel trailer in need of renovation.

Our own home is a similar structure (albeit smaller, and a few decades older), as is our own WWOOFer dwelling, the Albatross. So we had some experience working on such things, and we also wanted more (as we prepare for an addition to our home’s climate-controlled space).

After stops to visit family in New Orleans and our friends at other farms (Yokna Bottoms in Mississippi, Chastain Farms in Alabama), we arrived in Cedar Grove, North Carolina just after New Years, ready to spend two month living within the project we’d be working on – the renovation of the huge, rotting travel trailer they’d gotten for cheap a year before, hoping it would one day make a goat milking barn perhaps, or perhaps a dwelling for WWOOFers like us.

It was dark when we arrived, and cold. First impressions of the Tin Can were rather bleak. The floor was spongy at best, riddled with gaping holes, some patched with treacherous loose scraps of plywood, others wide open and serving as entrances for the cats. Not that they needed them – the front door frame was rotten and it would not close, and the remains of the back door had not been closed in years. It smelled dank and musty. The windows did not close, and the wind blew freely through the entire structure … chilly, but at perhaps a blessing, as fresh air.

Kristin had a pretty strong opinion about the best, most helpful course of action: “We … should burn this down for them.”

She was kidding … mostly. Maybe. It was hard to believe it could be salvaged, especially by the likes of us. But, we started chipping away at the project the next day, one step at a time. First up was demolition – Farmer Lish explained her plans for the space – where the old walls needed to be removed, where new walls might go. So we started tearing out the interior closets and walls, salvaging what might be useful later, sorting the rest into burn pile and dump piles. Sadly we didn’t take any good “Before” photos, as we were working to focus on the positives …

(*note: we were invited to stay inside the house, but refused – we wanted to stay in the Tin Can all winter!)

We learned where it was safe to step, and where you had to tiptoe across the exposed floor joists. I put my leg all the way through the bottom only once during this training. After the first freezing night, we taped plastic over our windows and started closing up the openings in the walls and floor that let the wind race through the East bedroom (the one that actually had a floor, mostly).

Although it was significantly warmer outside than back on our farm, it sure isn’t balmy in the northern North Carolina wintertime. It rained a lot, sometimes for days at a time. Mud was everpresent, of a slippery but not sticky variety. Sometimes there were ice storms, where the slow drizzle coated everything in a quarter inch of solid ice – causing trees to collapse and shatter under the weight. The power went out for a couple of days as a result. It was … rather exciting really, and strange and beautiful too.

Anyway, the weather wasn’t a really big deal for us, since we were mostly working indoors. We had a propane heater in our room with which to stay toasty at night, and thaw out during the work days. Otis had a new pair of tall rubber boots for mud puddle stomping. Lish and Wayne bought a car port; we set it up out back and moved a whole pallet of 3/4″ plywood into it, where it would stay dry and I could cut pieces down to size as we refloored the entire building. Kristin found a pile of storm windows and matched them to the appropriate holes, Frankensteining them into place as needed. I did some temporary junkgineering to the front door so it would open and close.

Every day from the time we woke up until we fell asleep, at least one of us was working on the Tin Can – and when we weren’t working on it, we were thinking about it. When it was wet out we worked on the interior, and watched the leaks to learn how water was entering. When it was dry out, we worked on the exterior. Honestly, I didn’t think we could get it near a final state during our 2-month stay … but as I mentioned, the Spinning Plates Farm and the Tin Can had felt meant to be from the get go. And as things tend to do when things are meant to be – things just kept falling neatly into place.

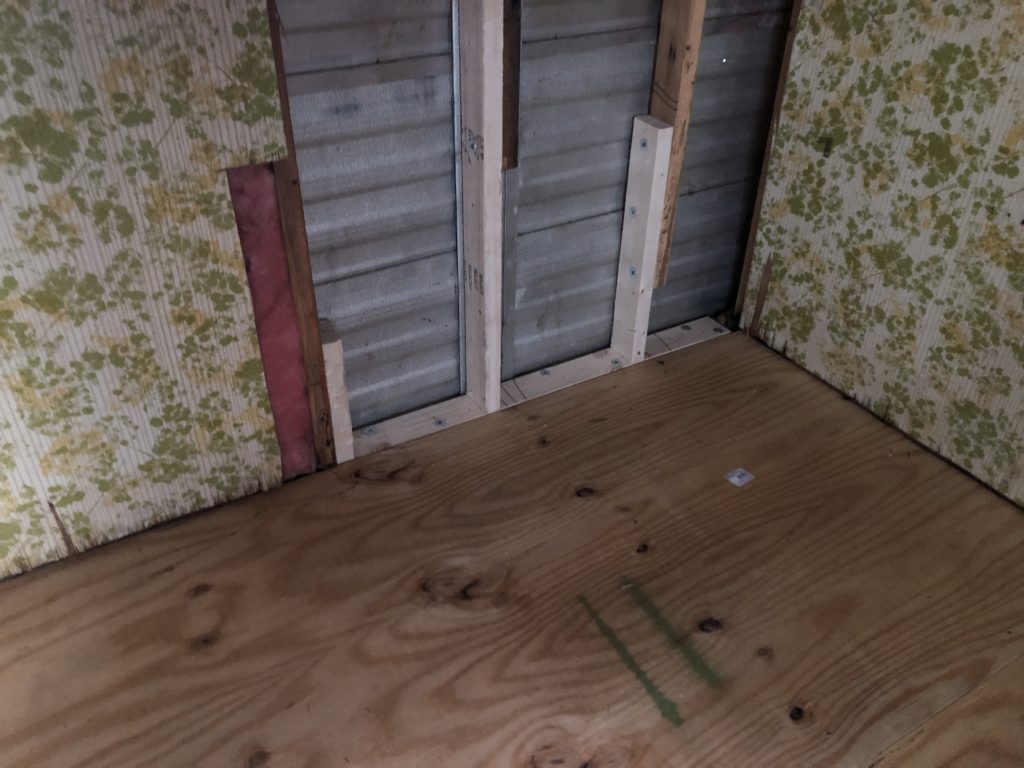

We started with the back bedroom, which had already had the particle board floor stripped out. Before we could put the flooring on, we had to address the damages to the subfloor and walls – several studs and floor joists were rotten, and the rim joists (the edge of the structure, where wall meets floor) on both sides of the NW corner were completely destroyed.

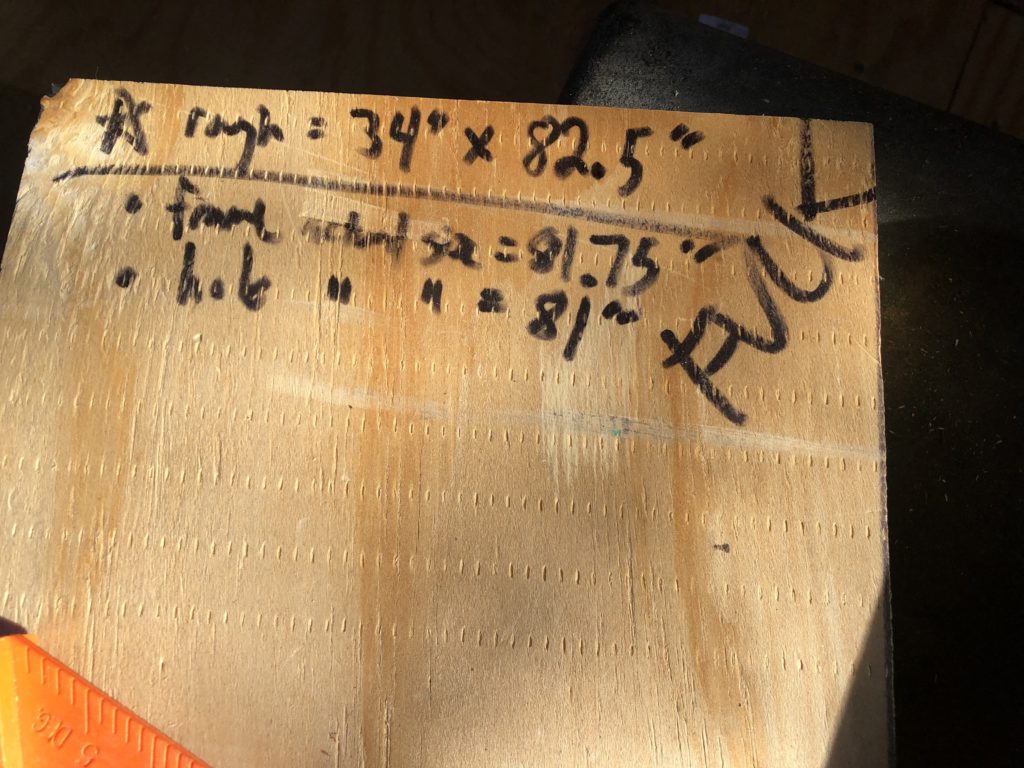

So while Kristin focused on identifying and repairing the many leaks that had been letting water into the structure, I learned how to cut out damaged subfloor and framing, and repair it – using mostly salvaged cedar 2x4s from an old outdoor playset. I talked to myself incessantly and wrote notes on every surface with a Sharpie, like a madman. Everything had to line up properly, support the weight of the roof – and provide level, flat surfaces for the replacement floor boards and wall panels that we hoped to install next.

Once that was done, the plywood went in, and we started letting the renovations flow forward from the back bedroom toward the other end, where we slept. Next up was the ruin inside of the missing back door – before we could put a new door in to keep out the rain, before we could build a floor, we’d have to replace all the rotten framing, and expand the doorframe to accommodate the full-size replacement door. Again the rim joist and the attached studs and joists had been totally destroyed – not only by the constant rainwater, but by the termites that the moist, rotting wood had invited in.

We tried to find a replacement door of the same size, without any luck – so they bought a standard exterior door and we cut the metal skin, and rebuilt the door frame entirely to fit it.

back doorway with rot removed

rebuilding the rotten subfloor

rebuilding the rotten subfloor

doorway with repaired rim joist and sill plate

termite or ant-hollowed floor joist

termite-ravaged rim joist

termite-eaten subfloor

old door frame top

repairing the subfloor

before cutting back the tin

original door frame

evil fire ants in the rotten old door header

realizing my new opening was too small

re-sizing the back door opening

brown boards are playset cedar

scraping glue from the joists – after this we decided to floor over the old

flooring over the rebuilt subfloor

escaped goat came through the project

between door header 2.0 and 3.0

new back door installed

From there the flooring project continued – first the old bathroom needed major work – a water heater in a closet had leaked for years and totally destroyed the floor and adjacent sheetrock, and the old toilet drain needed to be cleaned up and covered,

Then forward into the kitchen – where the hidden leak behind the cabinets had destroyed a section of wall and floor.

Around this time, we realized that I had been carelessly inhaling fiberglass stirred up by power tools and demolition. I had a sore throat and a nagging feeling that no amount of throat-clearing would fix.

repairing the kitchen wall, masked

So I started wearing a mask while I worked … and we turned up the priority of finding new wall panel material to cover all the exposed insulation left from the repair of the framing.

As you likely know, we are into old abandoned buildings – and the area was full of them, especially one specific type that we fell in love with – old tobacco curing barns, used to hang and dry the tobacco crops that once covered the local landscape. There were two right in the woods behind the farm – and when we asked, we learned that the neighbor just wanted them gone. So, of course we had to check them out.

And there beneath the blackened exterior siding boards (the builders had used fire to treat them against decay), we discovered beautiful rough-sawn pine boards, almost an inch thick, 8″ wide, and in lengths from 8 to 12 feet.

I knew this was what we needed – to not only serve functionally and inexpensively as wall panels – but to also build beauty, local history, and style into the structure we were bringing back from death’s door. It took some experimenting, but once I figured out how to loosen a board from the inside and then work the various options of a wonderful Wonderbar, I could quickly salvage the boards without damaging them in the process.

Otis chose his outfit for scouting

the stone step was brought back to use

we fell in love with the door

used the door as art outside the bedroom window

boards revealed

the first salvaged board

promised the building we would use its parts respectfully

scavenged

tools of the lumber salvage trade

prettiest siding boards as window accents

closeup of exterior board

heat from curing drove sap outward through the boards

taking home the bounty

taking home the bounty

the new interior wall

a cute light was born

from a local thrift store, a proper vintage wall hanging

A corner was turned, once these boards started to be deployed – and suddenly it seemed that the resurrected building just might be not only functional … but beautiful, too. Motivation, already high, became nearly obsessive, as the carpentry project blossomed into an artwork, something inspiring to work on and behold transforming.

There was still much to be done – a new front door and frame, repairing the subfloor inside the door, move our whole room out and rebuild the floor before replacing our bed, build an interior wall, source smooth cheap wall paneling from craigslist, panel all the holes in the walls, keep chasing leaks, … Kristin padded and carpeted both bedrooms and rebuilt the ravaged gutters and sanded/sealed the plywood flooring, I added water catchers over both doors, stabilized and leveled the front steps, used junked appliances from the demolition to create a temporary back step and stairs. We cleared away the piles of debris to the dump, jacked up and leveled the whole thing on concrete blocks … and just generally tried our best to make it all useful … and lovely.

And against all odds, it worked. We finished with a day or so to spare before we had to leave to return to the North to start a new season’s seeds – just enough time to throw a little house warming ice cream social, and relax for a couple of nights within the project that had defined our winter. It was intensely satisfying, and we both learned so much … perhaps primarily, about how capable we can be at making it work.

Unbelievable work and a beautiful finished project! You have a beautiful way of telling the story. Thank you for this amazing contribution to my friend’s farm. ❤️